The correct grinding method of the blade is crucial when choosing cutting tools. The grinding method of the cutting tool ultimately supports the blade itself, and the grinding method greatly affects its cutting method. Although there is no single “best” blade grinding method, each grinding method has its advantages and disadvantages, making it perform better in certain cutting tasks. Therefore, please continue reading to find the most suitable blade grinding method for you:

How does a knife work?

Technically speaking, a knife is a wedge-shaped object that separates materials by changing the direction of force. The wedge-shaped object converts the downward force at its thick end into a lateral force along its inclined side. When the material passes through, the wedge-shaped object will separate it. The thinner the wedge-shaped object, the easier it is to pass through the material; The thicker the wedge-shaped object, the higher its strength. A good knife must balance cutting efficiency and strength – if it is too thin, the blade will become too fragile; The blade is too thick and requires too much force when cutting. The type of blade grinding affects the balance of these characteristics by changing the geometry of the wedge, which ultimately determines how the blade passes through the material.

Flat grinding:

The characteristic of flat grinding is that the two sides of the blade are straight and inclined, gradually thinning towards the blade. There are two main types of flat grinding: full flat grinding and horse knife grinding.

Full plane grinding:

Completely flat ground, from the blade ridge to the edge, the entire width of the blade is conical. This makes them very suitable for slicing tasks, as gradually approaching the blade helps to separate materials in a smooth and uninterrupted manner. Therefore, many kitchens and slaughter knives use full surface grinding.

Flat blade grinding:

Grind with a flat blade until the blade is about halfway complete, then gradually taper towards the edge. This makes them more robust than full plane grinding, but at the cost of sacrificing slicing efficiency. When you want to perform rougher work, or if you need strength and reliability (such as survival knives), flat blade grinding is a good choice.

Concave grinding:

Concave grinding has concave surfaces on each side of the blade, curved inward. Generally speaking, concave grinding blades are thinner than other sharpening blades, making them excellent slicing blades that excel in precise cutting. Like flat grinding blades, you can increase the strength of concave grinding blades and make the geometric shape more blunt by placing the sharpening plate close to the blade. However, due to potential durability issues, they are not the preferred choice for labor-intensive tasks such as crushing. However, a unique advantage of concave sharpening is that they can be sharpened multiple times without making the blade thicker. In addition to traditional straight razors, concave edged sharpening is also common on hunting knives and everyday carrying knives, and its unparalleled cutting ability can bring benefits.

Convex surface grinding:

Convex grinding has outward curved surfaces on each side of the blade, opposite to concave grinding. Similarly, their characteristics are completely opposite, as they emphasize strength and stability rather than pure slicing ability. Convex edged grinding blades are usually more expensive than similar tools with different grinding methods, as they require more manual work to create the appropriate geometric shape. Usually, the main grinding extends all the way to the edge without a secondary edge slope, which makes them very suitable for woodworking and other carving tasks, while also making them more difficult to grind. Due to their durability and suitability for heavy cutting tasks, they are favored by various survivalists, jungle survivors, and outdoor enthusiasts.

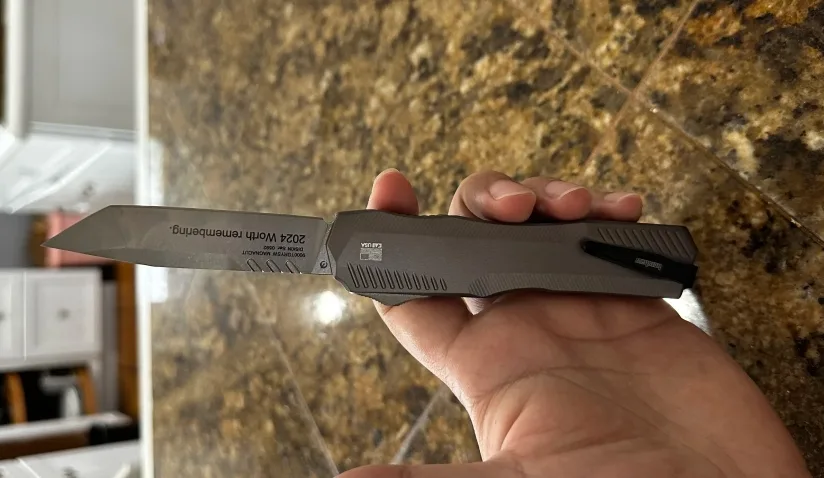

Chisel grinding:

The grinding of a chisel is asymmetric, with only one side having a sloping surface, similar to a chisel. This special grinding method works well in certain applications, such as kitchen knives specifically designed for right-handed chefs or defensive knives close to the body. However, their asymmetry limits their applicability in general applications, as they often ’tilt’ to one side during the cutting process.

Composite grinding:

Composite grinding achieves multifunctionality by combining different grinding types on the same blade. Each type of grinding is designed to accomplish different tasks, making the tools more versatile. Sometimes, their goal is to balance various grinding properties to optimize their overall performance. Sometimes, especially when it comes to customized cutting tools, they are just meant to showcase the skills of the tool manufacturer!

Choosing the appropriate grinding blade plays a crucial role in determining tool performance. Grinding is the foundation of blades and has a significant impact on their cutting ability. Although there is no universally superior blade grinding, each type of blade grinding has its own advantages and disadvantages for specific cutting tasks. We hope this page can help you find the most suitable blade grinding for your needs.